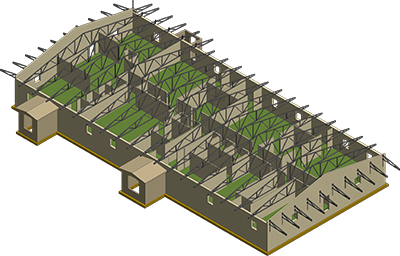

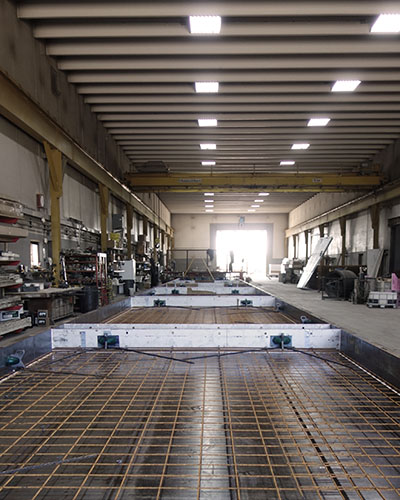

Design and Definition

Ola Precast is with your team from the beginning of the project.

Any project begins with design, and Ola Precast is ready to help! With full CAD-based prototyping capabilities, Ola Precast is with you from the first concept discussion. Let us help you model your design and then transfer that concept to our structural and civil engineering partners, line up your key contractors, and get your project off and running.